LEAK LOCATION SERVICE

We're specialists in advanced leak detection technologies designed to ensure the integrity and performance of geomembrane systems. As certified installers and experts in geomembrane testing, we offer innovative solutions to detect, prevent, and mitigate leaks in critical applications.

Discover our services below and protect your project with our expertise.

Arc Testing

This technique employs a brush or electrically charged rod that generates a spark when it detects a hole or defect in the membrane. It is ideal for detecting even the smallest holes or tears.

Arc testing relies on the application of high voltage and low amperage through a brush or cable. The high voltage allows the current to jump through small defects in the geomembrane, while the low amperage ensures operator safety and prevents damage to the material. When the current encounters a perforation or tear, it generates a visible spark that precisely identifies the leak point.

Arc testing is a non-destructive inspection method designed to detect leaks, perforations, and defects in exposed geomembranes.

APPLICATIONS OF ARC TESTING

Landfills: Leak detection before the placement of cover layers.

Reserviors and lagoons: Verifying impermeability in water or leachate storage systems.

Leaching ponds and mining: Inspection of geomembranes in leach pads and tailings storage facilities.

Industrial projects: Quality control of geomembranes used in chemical processes and hazardous waste storage.

Arc Testing is an accurate, fast, and efficient solution to ensure the quality of geomembranes in critical applications, as long as the conductivity or proper grounding requirements are met.

Why choose Arc Testing?

✅ Certified installers with extensive experience in spark testing.

✅ Accurate, efficient, and non-destructive testing methods.

✅ Detailed reports and recommendations for design and remediation.

Dipole Testing (Electrical Leak Location)

Dipole Testing is one of the Electrical Leak Location (ELL) methods.

The dipole test, also known as "Dipole Surveys" or "Dipole Leak Location," is a highly accurate and non-destructive method used to detect leaks or defects in geomembranes covered with soil, water, tailings, or any other material.

This technology uses two mobile electrodes (dipoles) that inject an electrical current into the surface of the covering material. If there is a leak in the geomembrane, the current flows through the discontinuity, allowing the precise location of the defect to be identified.

APPLICATIONS OF DIPOLE TESTING

Landfills and Waste Disposal Sites: Monitoring and maintaining the integrity of containment, even with multiple layers of cover. Detects leaks in geomembranes used in disposal cells and leachate ponds.

Mines and Heap Leaching: Ensures containment of leachate solutions in leaching pads, even after placing the 'overliner' layer. Detects leaks in solution storage ponds and tailings deposits.

Reservoirs and Artificial Ponds: Inspection of geomembranes in water storage or irrigation systems covered with soil, gravel, or liquids. Detects leaks without the need to empty the structure.

Why choose Dipole Testing?

✅ It is highly effective, even when the geomembrane is buried under soil, mining tailings, leachate, or water.

✅ Allows for inspecting liners in operation without the need to remove the cover material.

✅ Detects leaks of any size, from microscopic perforations to structural damage.

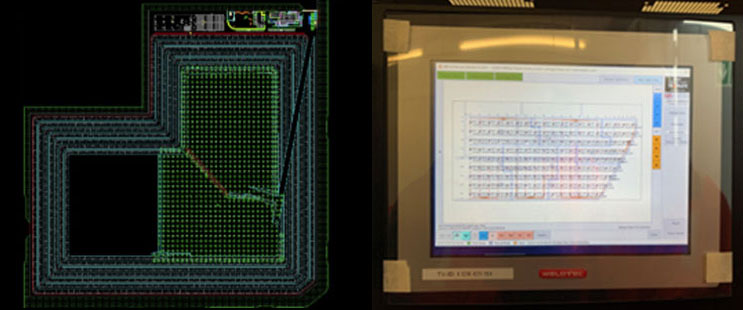

Permanent Leak Detection Systems

Permanent leak detection systems provide continuous monitoring of geomembrane systems, ensuring long-term leak detection and protection. These systems are installed beneath and around the liner and provide real-time data on potential damage or defects.

APPLICATIONS WITH PERMANENT SYSTEMS

Critical Infrastructure: Long-term monitoring for landfills, mining operations, and hazardous material storage.

Water Reservoirs: Ensuring sustained integrity in potable water and irrigation reservoirs.

Industrial Facilities: Continuous protection for storage tanks and containment ponds.

Environmental Projects: Early leak detection in environmentally sensitive areas.

Why choose Permanent Systems?

✅ Advanced technology for real-time monitoring.

✅ Reduced environmental risks and operational disruptions.

✅ Service provided by experts in installation and maintenance.

Why choose SAI for Leak Detection?

Comprehensive solutions

We cover all stages, from initial testing to permanent monitoring.

Customized services

We tailor our methods to the specific requirements of your project.

Certification and experience

Certified team with experience in leading leak detection technologies.

Industry experience

Contamos con la confianza de empresas líderes en minería, gestión de residuos, almacenamiento de agua y aplicaciones industriales.

Do you have a project underway? Contact us

Contact us today for more information about our services.