LARGE DIAMETER PIPELINE

PRODUCT

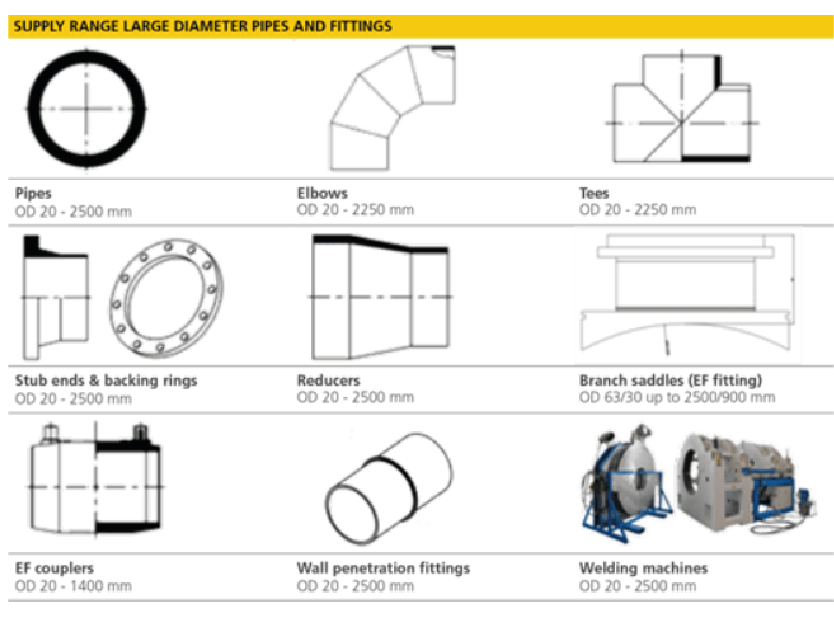

HDPE PIPES UP TO 3m DIAMETER AND CONTINUOUS SECTIONS UP TO 300m LENGTH.

High density Polyethylene pipeline or Polyethylene 100 (PE-100) with higher diameters than those commonly used. They have the purpose of decreasing costs and installation time due to their ease of handling and welding of panels by means of fusion and electrofusion.

It has been proven that the polyethylene tube has longer resistance to abrasion than other materials such as PVC, steel, ductile iron, cement and asbestos.Also featuring a high degree of impact resistance, being commonly used to transport drinking, salted and treated water; process sludge, cooling water and high pressure piping used in power plants.

APLICACIONES

- Rehabilitation of lines.

- Industrial processes.

- Tanks.

- Irrigation lines / drinking water.

- Mining.

- Cooling water pipes in industrial facilities and power plants.

- Sludge transport lines.

- Industrial wastewater systems.

- Water supply and discharge pipes in electric refrigeration.

- Shelters

- Cooling lines

- Sewage systems

- Renovation of underground roads

- Underground or surface deposits

- Water pipes and brine discharge in desalination plants

- Discharge of wastewater in maritime facilities

- Drinking water systems in maritime facilities

- Discharge collectors in maritime facilities

VENTAJAS

- Flexibility.

- Easy handling.

- Resistant to abrasion, chemical substances and weather.

- Corrosion-free.

- Non-toxic and physiologically harmless.

- Excellent chemical resistance.

- Longlasting.

- Impact resistance.

- Lighter (density of ~ 0.95 g/cm^3) ( 0.5491 oz/in³) reduces costs and provides buoyancy on water.

- Made to size accessories

100% leak-proof. - Easy and fast installation.

CARACTERÍSTICAS PHYSICAL CHARACTERISTICS

- Smooth or rigid HDPE and PE 100 tube.

- Reinforced HDPE tube with diameters up to 4000mm.

- Uniform wall thickness around the perimeter.

- Very smooth interior and exterior surfaces.

- Reduced ovality.

SIGNIFICANT TECHNICAL SPECIFICATIONS

Pipes and accessories are manufactured in accordance with ISO 4427 and EN 12201 standards.